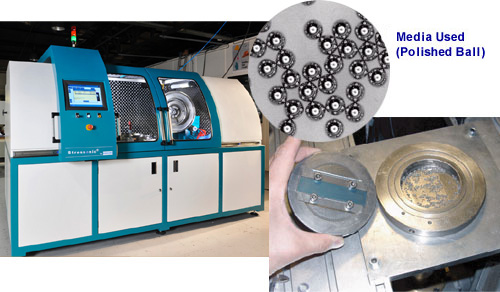

WAZA / KIWAMI / TAKUMI

Central unit

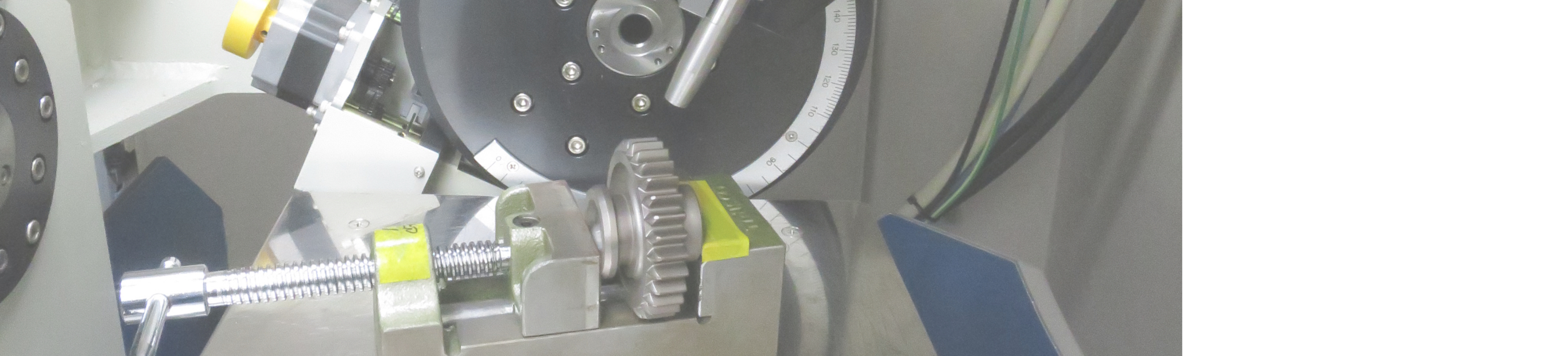

Peening head

[Ball type head] (Application sample)

Application:For shotpeening Shotpeening for Landing gear

[Pin type head]

Bowered gun

Application:Peenforming

Application:Welded toe

Shot media on the ultrasonic device will be injected by the ultrasonic, and produces peening effect on the surface of work piece.