WAZA / KIWAMI / TAKUMI

|

|

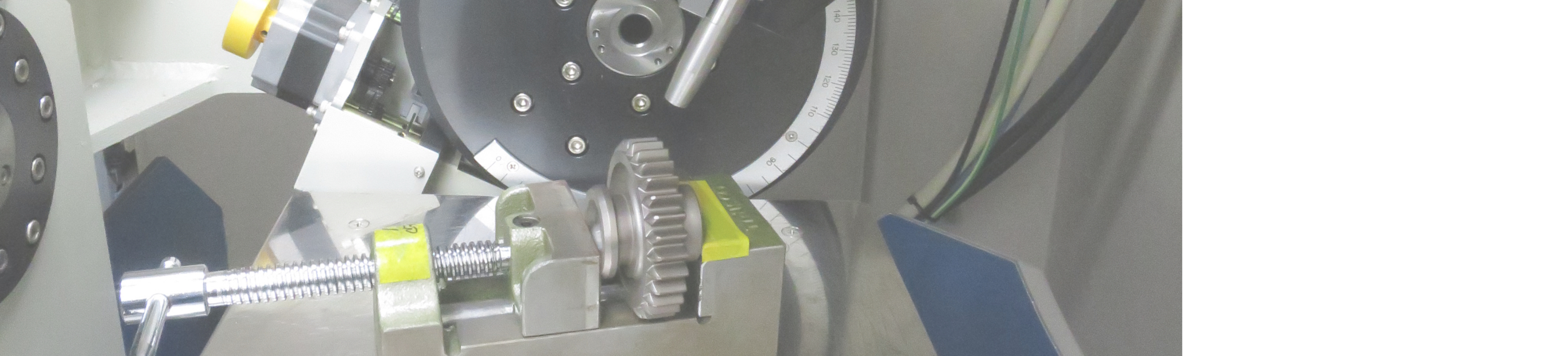

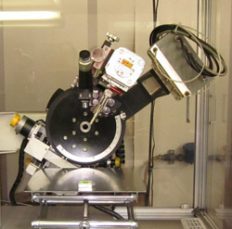

| Fig 1 PSPC | Fig 2 AutoMATE |

Table 1

| Tube | Measuring object material |

| Cr | steel, copper, brass, tin, nickel, carbide, chromium nitride, Ti-Ni shape memory alloy, aluminum oxide |

| Cu | zirconium oxide, α titanium |

| V | Magnesium, β titanium |

*We also have Cobalt (Co) tube.

Table2

| 4mm |

| 2mm |

| 1mm |

| 0.5mm |

| 0.3mm |

| 0.15mm |